With a current pool of one million IT engineers - half of whom are programmers - Vietnam stands at a pivotal crossroads. By focusing this vast talent on the semiconductor and artificial intelligence industries, the country could not only meet domestic demand but also become a key supplier to global markets.

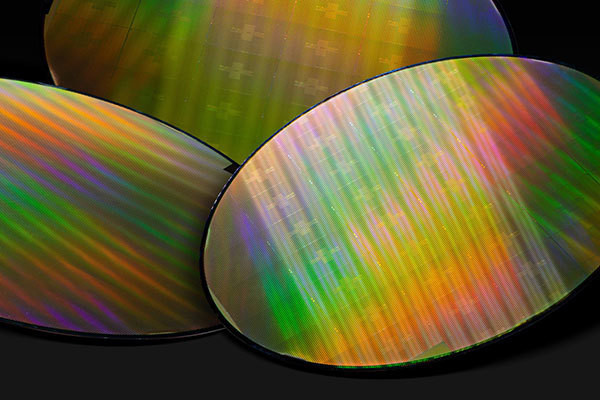

Vietnam’s journey in the semiconductor field began as early as 1979, but it has been anything but smooth. Now, history seems to be calling again. A new era is unfolding, presenting Vietnam with a once-in-a-century chance to become a global hub for semiconductor manufacturing - a dream that generations of Vietnamese are striving to fulfill.

In 2024, a joint documentary by FPT and Discovery chronicled Vietnam’s digital revolution, portraying the country’s rise from anonymity in global tech to becoming one of Asia’s leading digital economies. The 20-minute film outlines Vietnam’s transition into a technological powerhouse poised to lead the next tech revolution and become a global resource hub.

“FPT, along with other IT enterprises, has become a flock of Vietnamese birds flying across the world, asserting our nation’s position on the global digital map,” said FPT Chairman Truong Gia Binh.

The documentary, told in three parts, details the growth of Vietnam’s digital economy, with FPT at its heart as a pioneering force in IT development.

More than two decades ago, few believed Vietnam could develop software for the world. But through perseverance and strategic vision, FPT and its peers proved otherwise. Today, Vietnam’s one million IT engineers represent a force capable of propelling the nation into semiconductor and AI leadership.

In November 2022, FPT Semiconductor - a subsidiary of FPT Software - launched its first chip designed for Internet of Things (IoT) applications. The design was completed in Vietnam and manufactured and packaged at a facility in South Korea.

According to CEO Nguyen Vinh Quang, the creation of FPT Semiconductor reflects the dreams of many Vietnamese across generations. “Few know that back in 1979, we had the Z181 semiconductor factory, which supplied chips to Eastern Europe. With our ‘Make in Vietnam, Made by FPT’ principle, we aim to design and commercialize chips for markets like Japan, South Korea, Taiwan, the US, Europe, China, and beyond. We want to revive and complete the dreams of our predecessors.”

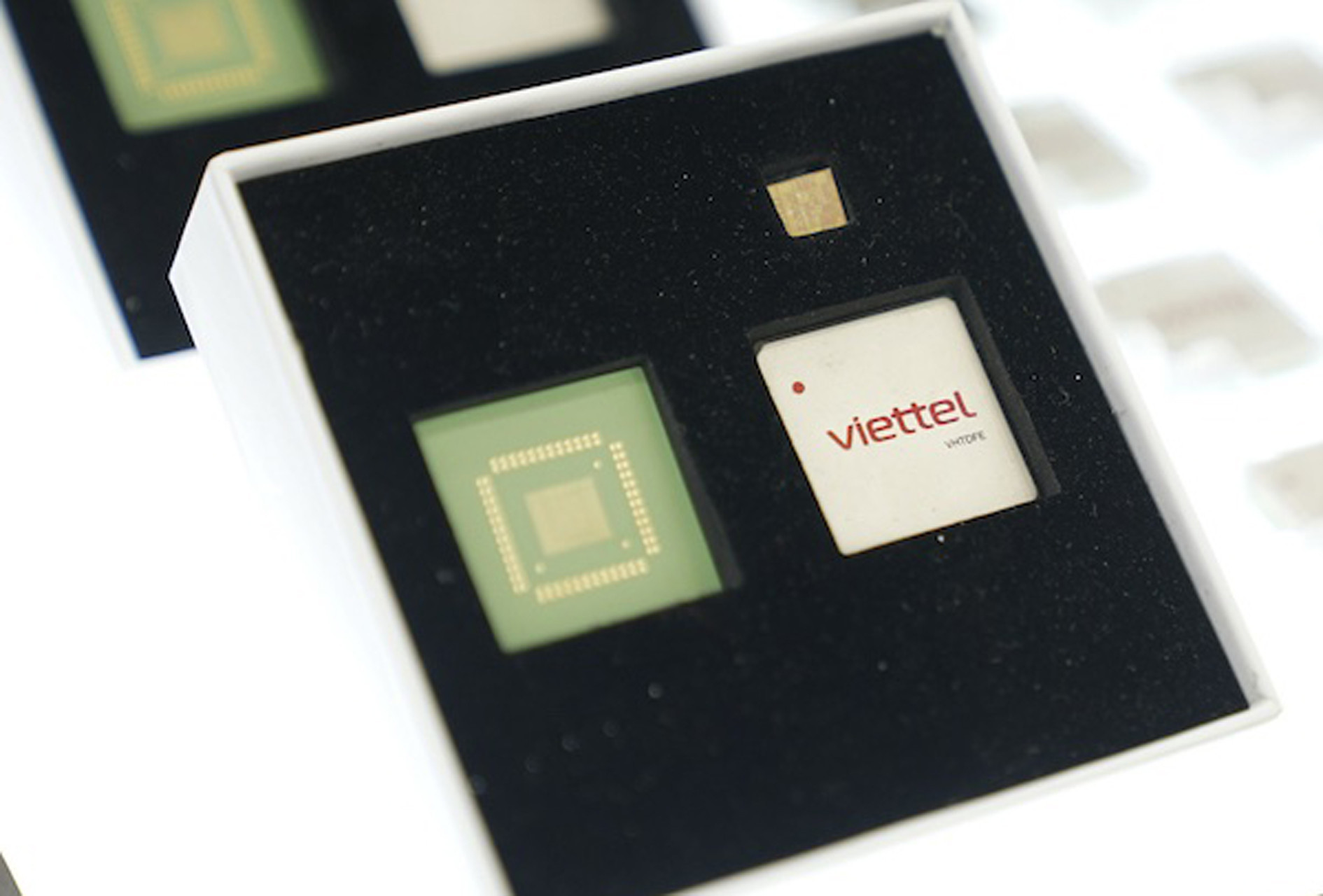

Today, FPT and Viettel are the two major Vietnamese companies active in IC design. While Viettel focuses on 5G technology, FPT specializes in PMICs - power management integrated circuits.

FPT chose PMICs because they are essential to every electronic device. These chips, which distribute power throughout a system like a heart pumps blood, constitute a market worth an estimated $1.3 trillion. With the global supply chain shifting away from over-reliance on China, Vietnam is well-positioned to become an attractive destination for electronics manufacturing.

Viettel has also advanced in chip design. It recently announced the successful development of Southeast Asia’s most complex 5G DFE chip, which can handle one trillion operations per second and serves as a core component of 5G base stations worldwide.

Major General Nguyen Dinh Chien, Deputy General Director of Viettel Group, emphasized that the path to developing semiconductors is long and requires steady progress in both research and commercial application. “We must create chips that meet the needs of domestic enterprises and national security. This will provide the foundation for future advanced technologies and global expansion,” he said.

A pivotal moment in history

Speaking at the Vietnam AI and Semiconductor Conference (AISC VIETNAM 2025), FPT Chairman Truong Gia Binh declared Vietnam a potential global tech destination, particularly in AI and semiconductors. He cited stories from global tech leaders like NVIDIA CEO Jensen Huang, who expressed amazement at Vietnam’s rapid progress.

“Vietnam isn’t just a beautiful country - it’s a vast, untapped space full of potential for global collaboration in AI and semiconductors,” Binh said.

Nguyen Khac Lich, Director of the Department of IT Industry (Ministry of Information and Communications), confirmed that the Prime Minister has signed a national strategy for semiconductor development through 2030, with a vision toward 2050. This marks Vietnam’s first long-term roadmap for the sector.

Lich emphasized that mastering R&D in semiconductors and electronics is essential if Vietnam is to move beyond assembly work. He highlighted the need to leverage the country’s geopolitical advantages and attract investment, while also focusing on infrastructure like electricity and water and implementing incentive policies.

In the short term, Vietnam must build a small-scale but high-tech chip fabrication plant to meet domestic needs, ensure national security, and enter the global supply chain.

Recently, the National Assembly passed Resolution 57, introducing special pilot policies to boost science, technology, innovation, and digital transformation. One key provision allows financial support for building Vietnam’s first chip factory, which will serve research, training, and prototype production.

According to Resolution 57, any domestic enterprise selected by the Prime Minister to invest in Vietnam’s first small-scale, high-tech chip manufacturing project will be eligible for state support.

“This is a once-in-a-century opportunity for Vietnam’s semiconductor sector to thrive amid ongoing geopolitical tensions,” said Le Quang Dam, CEO of Marvell Technology Vietnam.

Marvell's data shows that by 2025, Vietnam will have around 60 companies working in IC design. Back in 2000, there were only 30 engineers in the field. That number soared during 2005-2010 and is expected to reach 6,000 advanced semiconductor engineers in 2025.

Dam emphasized the importance of uniting Vietnamese and overseas Vietnamese experts, regardless of industry, to create lasting value. “This opportunity won’t come on its own. We must create it. With clear strategy, government support, and unified human capital, Vietnam can become a major player on the global semiconductor map.”

Thai Khang